Product Features:

This product is suitable for the production of wireless terminal equipment (mobile phones, models, routers, drone motherboards, car GPS motherboards, etc.) SMT line tail,Universal before and after the furnace, instead of manually performing the work of shielding cover, crimping, die cutting, barcode reading, etc.

Features:

1. Suitable for single or double-sided up to 4 kinds of disc materials or 6 kinds of die-cutting parts, fast speed and good stability

2. It can be placed on the front of the furnace / behind the furnace to install the shielding cover, saving the manpower of loading, increasing production capacity and improving product quality;

3. Compatible with carrier and non-carrier PCB board mounting shield cover;

4. bilateral feeding, four to six disc feeder stations, disc feeders have a choice of 2 to 10 discs, to meet the needs of different products, docking with the production line to achieve line production;

5. Efficient multi-axis working head: 6 vacuum nozzles, the mounting speed can reach 2.5S/PCS, and the pass rate is ≥99.8%;

6. high-precision transmission positioning system: the use of imported linear servo motor, grating scale, closed-loop control. Significantly improved speed, accuracy, stability and equipment life;

7. It can increase the functions of applicable tape, label placement and QR code scanning, so that the equipment can be diversified and provide customers with convenient production mode;

8. comes with 2D barcode reading function: automatically read the barcode after the label is posted;

9. the equipment can be changed to the use of Odd-form Component Inserter.

project | AM3100S Shielding Cover SMT Machine |

Basic configuration | Standard feeding platform; belt type three-stage transmission; 6 placement heads; MK camera; part recognition camera; XY linear motor, grating ruler; THK linear guide |

Mounting accuracy | Repeat positioning: ±0.01MM, positional accuracy: ±0.03MM 3sigma |

Mounting speed | Mounting speed: 2.5 s / shield cover |

Pass rate | Pass rate ≥99.8% |

Shield cover size | Minimum: 5*5*0.04 (MM) Maximum: 75*75*0.2 (MM) |

TRAY incoming material size | Width range: 152MM-255MM length ≤ 320MM |

PCB size | Minimum: 50*50 (MM), maximum: 320*210 (MM), thickness <5MM |

PCB clip width | 〉3MM |

Track interface | SMEMA |

Fixture reflow device | Reserve jig reflow device channel |

Feeder (number of options) | Multi-disk Feeder (10 discs), Duel-disk Feeder, package label feeder, package thermal silica chip feeder |

Tape and shield cover feeder | Support shield cover tape feeder |

Targeting | MARK positioning and machine vision positioning |

Numberof placement heads | 6 placement heads for up to 6 types of materials |

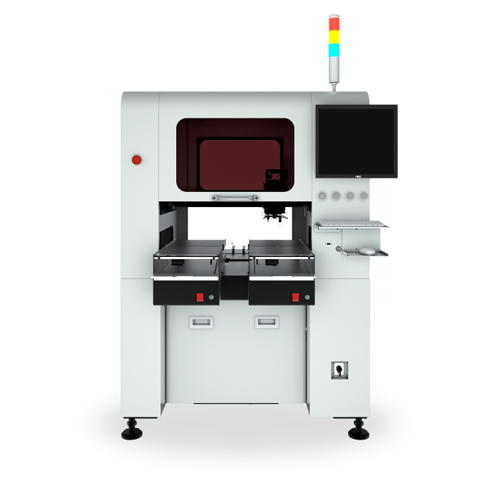

Host size | 1200X1330X1660MM (length * width * height) with transmission track |

Multi-disk Feeder size | 320*910*800MM (length * width * height) (tail protruding host 430MM) |

power supply | Single phase AC 200~240V 50/60HZ 10A 3.3KWH |

Air pressure | Dry air 0.45-0.6M pa |

equipment weight | About 1600 kg |

Software management | Can be docked with MES system and MTS tools, with built-in WI function, reverse foolproof function |

extensions | Labeling, thermal insulation cotton, die-cutting |

other: | More compatible for the placement of shield covers for all communication products |

@2017 Shenzhen Wali Automation Co., Ltd. All rights reserved